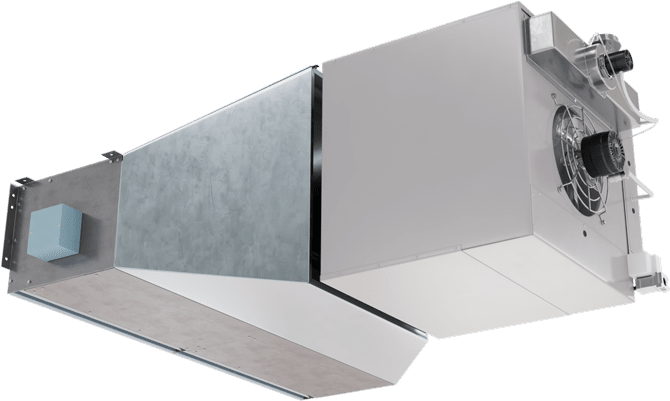

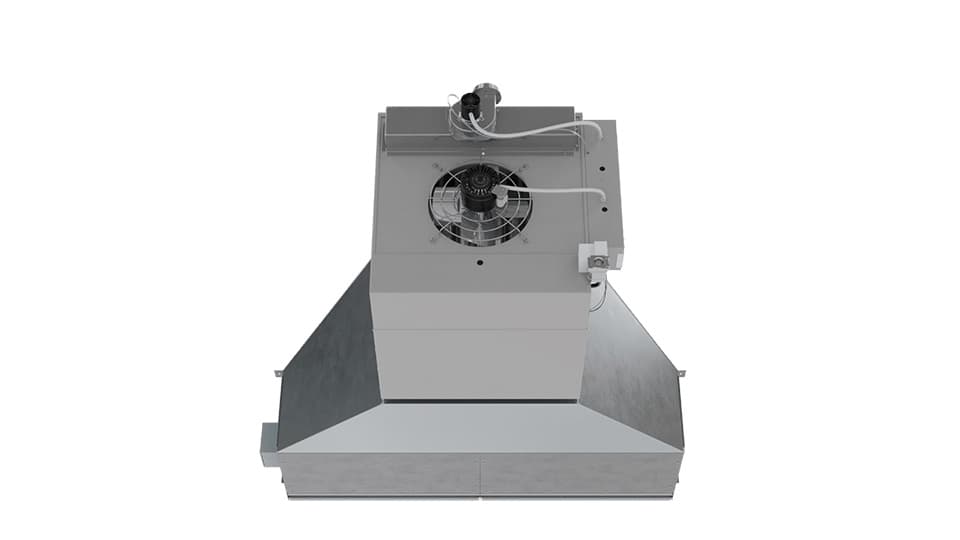

Key Design Features

- Outer cabinet constructed of 18-gauge 304 stainless steel with #3 finish

- 3/4 HP ODP (Open Drip Proof) direct-drive dual-speed motor(s)

- High-efficiency discharge plenum with adjustable air foil vane (+/-20˚)

- Top and bottom access panels for servicing and removal of motor-blower assembly

- NEMA 12 control panel

- Factory mounted 18-gauge 304 stainless steel transition duct(s)

- AGA/CGA labeled gas heater(s) with power exhaust, direct spark ignition, and tubular heat exchangers

- Convertible open and closed combustion

- Natural gas or propane fuel types

- Standard single point power connection

Recommended Air Curtain Controls

- Activation by 24V magnetic door switch

- Toggle disconnect switch

- Hand/Off/Auto selector switch

- Heat On/Off selector switch

- Digital thermostat

360 View

Cost Savings Calculator

This tool will help you understand the cost savings you could expect based on the air curtain you select and your input on how and where it will be used.

Calculate NowAir Curtain Selector

This tool is designed to help you find the best air curtain

for your situation by asking a few basic questions.